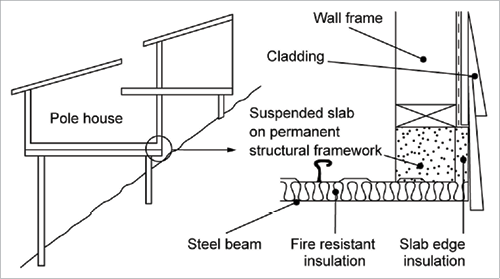

Pouring concrete will be carried out using mobile pumps / concrete bucket The concrete shall be vibrated Spare vibrators shall be kept in case of emergency Fresh concrete shall not be permitted to fall from a height of greater than 150 meters without the use of adjustable length pipes or elephant trunksSuspended Slab on Metal Deck A quick and easier way to build suspended slab is to use metal deck if it's accessible This approach to concrete slab construction is very common in commercial construction Using metal deck as forms for cement slabs over garages is a great alternative to building forms with wood and/or scaffolds Pourinplace Concrete is the first option for concrete slabs and infrastructure, as well as for units such as beams, columns, walls, ceilings, etc Usually, concrete is transported to the site in a nonhardening state and is usually transported in pre concrete trucks

Suspended Concrete Slab Project On Commercial Drive

Pouring elevated concrete slab

Pouring elevated concrete slab-For all concrete, wet cure minimum 4 days, 7 is preferable To reach the design strength, cure for 28 days unless you pour cylinders with the original pour and break them to check strengthA professional should be engaged to pour the concrete from a reputable premix company This will ensure that the concrete is at the specified strength Prior to pouring, soak the slab bed with water to prevent moisture loss Once the concrete is poured, add control joints where required

Pin By Ron Koski Tuuri On Structural Drawing Concrete Slab Metal Deck Steel Frame Construction

Ensure aggregates may pass through during concrete pouring Fix slab bottom bars Arrangement shall be short span at the bottom and longer span above the short span Check clean spacing of reinforcement from shutterA suspended slab is raised off the ground and has an accessible subfloor area In a residential situation, the slab is around 0mm thick and is supported by external subfloor walls of brick or concrete block etc The slab is also supported by freestanding brick or concrete piers To reduce the concrete slab thickness a sheet metal productA concrete slab is susceptible to soil expansion and contraction, which can lead to cracking Posttensioning is a form of prestressing concrete to provide reinforcement and overcome concrete's weaknesses Posttension concrete slabs are used to create a monolithic (single pour) slab that is stronger than a traditional slab without

For large slabs, it's best if the truck can back up to the concrete forms Avoid hot, windy days if possible This kind of weather accelerates the hardening process — a slab can turn hard before you have time to trowel a nice smooth finish If the forecast calls for rain, reschedule the concrete delivery to a dry day Rain will ruin the surfaceSteps Involved in Pouring Concrete over Existing Concrete Slab Step 1 Cleaning Old Concrete Surface Sweeping dirt's debris over the existing concrete slab will allow bonding to take place This includes removing sand, dead leaves, and gravel One of the best tools that can be clean all the debris out of crack is a stiffbristle broomA method of constructing a suspended floor is described in which a plurality of beamforming formwork assemblies are located in substantially parallel alignment, the beamforming formwork assemblies are supported in support assemblies on a support base in stable equilibrium, a plurality of floorforming formwork assemblies are located between the beamforming formwork

Polishing of suspended slabs usually takes place much longer after the concrete was placed, which increases concrete strength due to extended curing The polishing contractor could be dealing with Elevated concrete slabs (also known as suspended concrete slabs) are most commonly found in commercial offices, parking garages, and other multistory heavyuse buildings These pours require a bit more skill than your everyday residential concrete driveway and will need to be carried out by a professional contractorConcrete slabs can weigh more than 800 pounds and are at risk for tipping, shifting, and falling on those around themAlmost every job that you can have as a construction worker carries a possibility of working with concretewhich ultimately increases your chances of sustaining serious injuriesConcrete DangersConcrete construction accidents

Concrete Floor Slab Construction Process The Constructor

Concrete Slab Wikiwand

I'm designing a suspended concrete slab over a concrete basement walls for a house garage 24'X24' plan dimension Ideally I would like to avoid beams, but I know locally (Missouri) it has been done with one or two steel W shape beams to support the slabPrecast slabs are manufactured off site and craned into place, either in finished form or with an additional thin pour of concrete over the top They can be made from conventional or posttensioned reinforced concrete, or from autoclaved aerated Pouring interior concrete slab over existing, cracked concrete slab 4 Answers I am turning part of my carport into a new living room I am going to pour a concrete slab about 4 inches thick over the existing carport floor which is a concrete slab The existing slab has a few cracks, the largest of which is about an 1/8in

Suspended Concrete Slab Project On Commercial Drive

Structure Suspended Slab Home Building In Vancouver

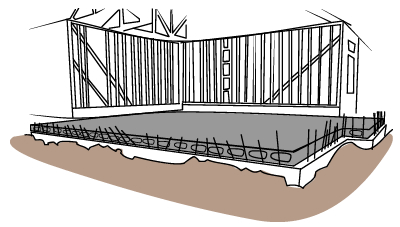

We typically pour / 8" at the house and fall to / 7" towards the landscaping over a typical span of 7 feet We ledge the concrete slab on the foundation at the house by holding the framing towards the inside and we pour over the outside foundation wall and past it by 1 1/2"The question does not say whether the slab is designed as conventionally reinforced, or to be post tensioned Nor how long it will be until more concrete will be available With a PT slab, it is usual to apply an amount of initial PT after (say) 2Precast suspended slabs are constructed by pouring the slab in a formwork on the ground and then lifting the slab into its suspended position in the structure Formwork is installed on top of the struts and beams Reinforcement is assembled on top of the formwork Concrete is then poured into the formwork

First Floor Concrete Slabs What You Need To Know Eco Built

Structure Suspended Slab Home Building In Vancouver

Method Statement for Pouring Concrete on Slab on Grade After backfilling works the next is casting slab on grade (ground), make sure that all the area beneath grade slab have been properly backfilled and compacted Approval must be obtained from the Engineer for waterproofing and backfilling works prior to start slab on grade castingCement Slab Installation Labor, Basic Basic labor to install cement slab with favorable site conditions Layout pad height and slope Lightly grade and remove loose soil Set forms and reinforcing Pour and finish concrete Excavation, gravel base layer, compaction or hardscape demolition not included 500 sq ft maximum Is this episode of concrete ninja will you do a job with Tim and the boys for Jeff Lennox It is a 300 m² suspended slab one story high some of that is over

How To Pour A Concrete Floor Homebuilding

Concrete Placement Concrete Construction Perth Westcon Contracting

Pouring a concrete slab and getting it level is very important Start on one side and screed off the top of your forms and the middle pad using a magnesium screed Kind of ride it on the back edge and pull the concrete down using small 6 to 8 inch strokes Using a sawing motion works OKSlab R‐Value Table Insulation and Fenestration Requirements by Component E ClimateZone Slab R‐valued 4 10, 2 ft 5 10,2 ft 6 10,4 ft 9 d R‐5 shall be added for heated slabs Heated slab slab‐on‐grade construction in which the heating elements are in contact with, or placed within or under the slab Posted I am trying to create garage foundation walls to support 8" preformed cement slabs for a room under the garage The manufacturer recommends a 12" foundation shelf inside the stem walls to suspend the slab and then be able to pour the 4" garage floor slab on top I am struggling finding a way to create this type of

Ground Floors Concrete And Suspended Timber Types Of

Structure Suspended Slab Home Building In Vancouver

Deflection of Composite Deck Slabs" in Concrete Construction, September 1997;The 6 inch suspended slab in detail 21 weighs 75 pounds per square foot but the formwork should be designed to carry psf due to the weight of workers and equipment used during pour That is why concrete formwork for suspended slab has a lot more columns and beams compared to the normal residential floor framing The following details the stepbystep process for pouring a concrete slab from beginning to end Safety First Designate and Prep Area Create Concrete Forms and Level Grade Install Rebar Pour the Concrete and Spread Screed, Float, and Trowel Round Slab

Building 1 Parkade Suspended Slab Cardel Lifestyles Blog

5 Things To Look For When Inspecting A Suspended Concrete Slab

To reinforce a 4" concrete slab or driveway with steel rebar, determine the grid spacing and rebar size – #3 or #4 in a 12" to 18" grid Use 2" rebar chairs to support the rebar in the center strata of the pad Overlap joints by a minimum of 12" for #3 and 15" for #4, bind with wire ties, and keep the steel 3" back from theAfter the reinforcements work is completed and all the necessary approvals are taken, pouring of concrete can be done Concrete can be poured into the slab by using the pump car or manually concrete can be taken into the slab Concrete Pouring in Piles Concreting of piles is different from the other concreting methods I am under agreement on pt that is a renovated barn There is a 2 car garage bay with a suspended concrete slab

Smartslab Solutions In Suspended Slabs

Q Tbn And9gcs Jfito3osvkszwu Nlnbmliouqmfy 2pwavm Wfzs4k Cjzrf Usqp Cau

264 Posts #5 i am doing this right now, adding on to a existing slab, a general contracter advised me to drill into the existing slab with a spacing between holes every 32 inches and no less than 2 ft from a corner, insert a 5/8 dia rebar in 6 inches with 6 inches sticking out , this will anchor the new slab to the footer ofWhen working with cementbased products, always wear eye protection and waterproof gloves Step 1 Prior to placing concrete forms Construct the form with 2x4 or 2x6 lumber and secure in place by wood stakes and deck screws Excavate the slab area to a depth of about 7 inches, allowing 3 inches for a gravel base and 4 inches for concrete Step 2An overview of the structure types for suspended slabs and grids An overview of the structure types for suspended slabs and grids

Analyzing The Efficacy Of A Suspended Concrete Slab In Formwork And Concrete Construction Asfct Concreting Service

Precast Garage Floor Forterra

Concrete slab issues and defects aren't always easily identifiable, but should you find an issue, it's important that you deal with it as soon as possible Hairline fractures and minor defects can grow into major problems in just a short period of time While it can be easy to play the blame game, it's important to start by addressing theConcrete slabs also results in flexural crack formation and possible failure Cracking in concrete can be reduced significantly or eliminated by observing the following practices 1 Use proper subgrade preparation, including uniform support and proper subbase material atPlacing excessive amounts of weight on top of a concrete slab can cause cracking When you hear a concrete mix has a strength of 00, 3000, 4000, or 5000 PSI, it is referring to the pounds per square inch it would take to crush that concrete slab When it comes to residential concrete slabs, overload of the actual slab isn't all that common

Structure Suspended Slab Home Building In Vancouver

Garage Foundation Foundation Footing Suspended Concrete Slab

The concrete is basically just flooring material and does not support its own weight This has all the advantages of concrete as a surface durability, hardness, you could bond tile to it, etc But it does not rely on the concrete for actual structural strength of the building, as a metalpan would in a commercial settingAnd ACI 302IR04, "Guide for Concrete Floor and Slab Construction" ASCC concrete contractors will work with all parties in addressing these issues If you have any questions, contact your ASCC concrete contractor or the ASCC Technical Hotline at (800) I am pouring a concrete slab on my first floor Slab will be under south facing windows only Slab will be 10' wide and 46' long I want slab to hold heat, so not using light weight concrete I will have pex for additional heat if needed I intend to use 2x8s on 16" center to support concrete This will remain after pour 35" floor will have 1/2" rebar grid on 12" centers

Strength Stability And Performance The Right Floor For Your Build Renew

Suspended Concrete Floors Maximum Size Of Pour Allowable And Location Of Construction Joints Pdf

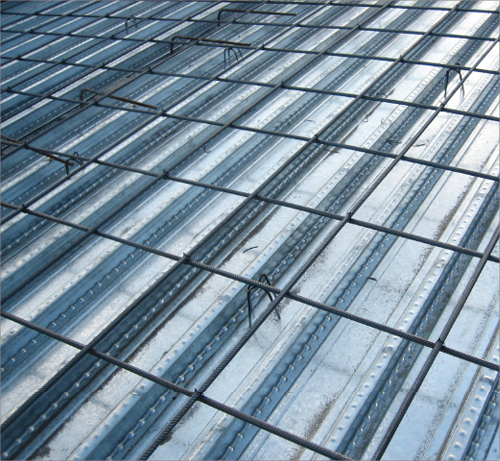

Suspended slabs are made of concrete and steel mesh, the same as a ground slab They are normally prefabricated offsite, and transported by truck Some slabs have hollow channels running through them these 'hollow core slabs' are used to help reduce weight, and also to allow cabling and piping to be run through the slab This rebar grid is sitting on chairs, a setup that keeps it suspended at the proper height You won't be able to use chairs if you have to distribute the concrete throughout the form with a wheelbarrow If that's the case, use the hook on the edge of the concrete placer to pull the rebar up into the center of the concrete as you pour Suspended concrete slab Posted in General Discussion on 0335am * I am designing a house for a couple that wants a concrete slab on their patio They also want storage under the patio because of the slope of the lot Since I

Concrete Slab Floors Yourhome

Suspended Garage Slab From Design Build Specialists Steel Concepts

🕑 Reading time 1 minuteConcrete floor slab construction process includes erection of formwork, placement of reinforcement, pouring, compacting and finishing concrete and lastly removal of formwork and curing of concrete slab ContentsConcrete Floor Slab Construction Process1 Assemble and Erect Formwork for Slab2 Prepare and Place Reinforcement for Slab3 Pour,Only 6"8" concrete topping required Using a composite steel and concrete design the floor slab can be thinner than conventional residential suspended slab systems This results in a cost savings in concrete of 2550% Pouring a Structural Slab Over Living Space The nested ribs of the decking add integral beams to the concrete, strengthening the slab The slab needs to slope 1/8 inch per foot, so a sloped ledge was designed into the exterior foundation walls for the steel decking to rest on

Suspended Concrete Slab The Labbe House Project

Pin By Ron Koski Tuuri On Structural Drawing Concrete Slab Metal Deck Steel Frame Construction

Alternative to suspended slab , 18 PM I'll be pouring my foundation slab this week and am in the planning stages for the rest of the oven I'm not too keen to deal with forming, setting the steel and pouring a suspended concrete slab for the hearth so I'm looking for alternatives My precast oven will weigh about 1600# finishedHow long curing (ponding) should be done in ceiling concrete slab? You can pour slabs in sections, you just need to pin them together with rebar so that they stay in alignment This is how concrete road surfaces are done Malcolm is right too, if you have your slab not flat or not level everything else becomes a problem since you're constantly having to try to compensate for the uneven slab

Suspended Garage Slab From Design Build Specialists Steel Concepts

A Different Kind Of Slab Daily Monitor

Suspended slabs are upper floor slabs that are not in direct contact with the ground and form the roof or the floor above the ground level They usually form the upper stories house floors but can also be laid on top of a prebuilt wall to form a floor Concrete slabs come in many forms and can be used to provide great thermal comfort Number five of things to check when checking a suspended concrete slab before a concrete pour is to ensure that the correct cover is achieved to the slab reinforcement This is the last item in importance because it can pretty easily be rectified on site

Icf House With Concrete Suspended Slabs Youtube

Solutions To Pour Strips In Conventional Cast In Place Concrete Pour Strips

Concrete Slab Wikiwand

Lightweight Suspended Concrete

File Pouring Concrete Slab Under Suspended Resilient Tie Block Rail 04 16 19 Jpg Wikimedia Commons

Structure Magazine Concrete On Metal Deck

8 Suspended Slab Ideas Steel Frame Construction Steel Structure Steel Deck

Formdeck Insulated Suspended Slab System Formcraft

This Is Everything Inside A Suspended Slab That A Lot Of People Do Not See We Have A Concrete Beam To The Middle Left Han Storey Homes Ideal Home Construction

Why Polishing Suspended Concrete Slabs Is More Likely To Disappoint Customers For Construction Pros

Blog Archives Neoterra

Concrete Floor Designing Buildings Wiki

Structure Suspended Slab Home Building In Vancouver

First Floor Concrete Slabs What You Need To Know Eco Built

Concrete Slab Floors Yourhome

1

Suspended Garage Slab From Design Build Specialists Steel Concepts

First Floor Concrete Slabs What You Need To Know Eco Built

Concrete Slab Wikiwand

Suspended Ground Floor Construction Mezzanine Floor Supplier And Installers Prestressed Concrete

Concrete Construction Smarter Homes

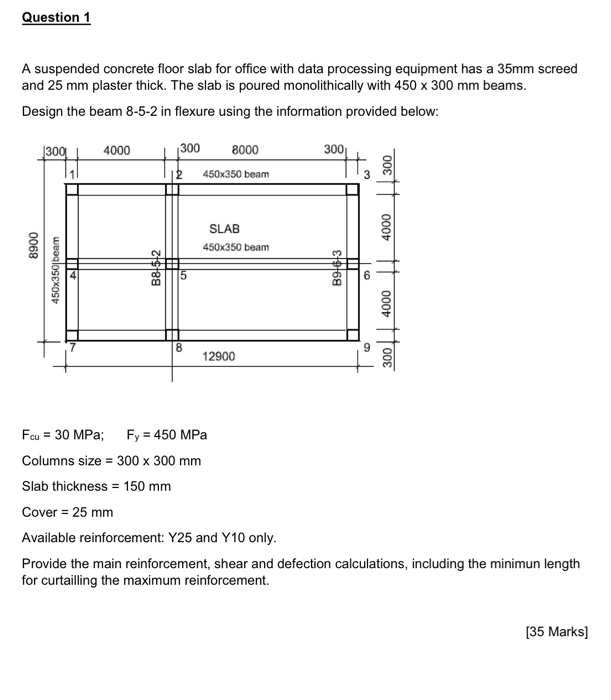

Question 1 A Suspended Concrete Floor Slab For Office Chegg Com

Concrete Forms And Pouring A Concrete Slab Diy Family Handyman

Method Statement For Formwork Reinforcement And Concrete Works

Structure Suspended Slab Home Building In Vancouver

Suspended Bondek Slab Construction Process By 3g Group Property Development Youtube

Monolithic Slab Monolithic Monolithic Concrete Slab Diy Concrete Slab Cement Floors Diy Concrete Slab Pouring Concrete Slab Slab

Spire Development Our Crew Was Hard At Work Pouring The Parkade Level Suspended Slab Can You See The Building Starting To Take Shape T Co Mybqjmjdls T Co Uli52su3kg

A Primer For Pouring Concrete Powerblanket

Suspended Garage Slab From Design Build Specialists Steel Concepts

What S Possible With Suspended Slabs On Metal Deck Concrete Construction Magazine

Pouring A 50 Ton Elevated Concrete Porch Slab Youtube

Guidelines For Poured Concrete Over Corrugated Metal Home Improvement Stack Exchange

5 Things To Look For When Inspecting A Suspended Concrete Slab

Portable Used Steel Suspended Floor Slab Concrete Pouring Table Formwork System High Strengh Steel And Birch Ply Buy Flying Table Formwork Used Steel Shuttering Material Waffle Slab Formwork Product On Alibaba Com

How Are Suspended Slabs Built Quora

Concrete Slab Floors Yourhome

Frequently Asked Questions At First Floor Slabs

Forming Concrete Suspended Slabs Youtube

Exclusive Residence Suspended Slab Extension Concrete Pour Youtube

Different House Slab Types For Building Homes In Geelong Torquay

Concrete Slab Floors Yourhome

Frequently Asked Questions At First Floor Slabs

Shoring Support For Concrete Slabs Efco Formwork Solutions

Concrete Slab Or A Timber Joisted Floor Which Is Best Partridge

How To Pour A Perfect Concrete Slab Powerblanket

Q Tbn And9gcqy7ubsx U7mieeqaoa2kew4 Arn9ulfocsrbmt8o1wfmrcwew Usqp Cau

5 Things To Look For When Inspecting A Suspended Concrete Slab

Construction Joint In Slabs The Structural World

The New Zealand S First Passive House Concrete Floor Slab Second Pour

Suspended Garage Slab From Design Build Specialists Steel Concepts

Suspended Concrete Slab Suspended Slab Cement Slab

How Are Suspended Slabs Built Build

Final Suspended Slab Youtube

Pouring Concrete Suspended Slab Gallery Tullipan Homes

Methods Of Pouring Concrete As Per Aci 304r 00 Recommendations

The New Zealand S First Passive House Concrete Floor Slab Second Pour

Method Of Statement Template For Concrete Slab

Question How Do I Carry Out Large Area Pours For Suspended Slabs

Suspended Slab Subfloor Build

Cornerstone Building Civil Engineering Suspended Slab With Removable Formwork Ready For Concrete Pouring Looking At The Example In The Image The Steel Bars Are There To Withstand And Counteract The

Suspended Slab Concrete Pour Youtube

Suspended Garage Slab From Design Build Specialists Steel Concepts

Pour Strip In Concrete Slab Rebar People

Concrete Suspended Beam And Slab Construction Process Steel Rebar Reinforcement Placement Formwork Youtube

How To Build A Custom Home Part 18 Concrete Slabs Basement And Garage Floors The Bold Company

New Home Pouring A First Floor Suspended Slab Youtube

The New Zealand S First Passive House Concrete Floor Slab Second Pour

Pouring The Slab And Framing The Walls Greenbuildingadvisor

Concrete Slab Floors Yourhome

Concrete Slab Wikiwand

1

Jj Duffy Demolition Pouring Concrete For Suspended Floor Slabs All Civil Works Completed By Jjd

Suspended Slab And Beams Method Of Construction Constructupdate Com

5 Things To Look For When Inspecting A Suspended Concrete Slab

5 Things To Look For When Inspecting A Suspended Concrete Slab

Concrete Slab Abis

Cost Of Concrete Slabs Serviceseeking Price Guides

0 件のコメント:

コメントを投稿